Re-Inventing the Tire

How NWR Recycles Scrap Tires into Useful Rubber Products

PUBLISHED IN MAR 2022

THE HISTORY OF TIRES

The wheel has been an economic staple since roughly 3,500 BC, helping us move things faster and farther. Efficient? Certainly, but a bumpy ride to be sure.

In 1888, the invention of the tire ushered in a new era of road transport and safety. The first ever leather tires evolved into hard airless rubber rings, and finally into the pneumatic tire we know today. Innovative new textures (hello, tire tread), synthetic rubber materials, and inventive approaches to tire performance have all shaped the modern rubber tire as we know it.

These days, winter tires, summer tires, all-season tires, and all-weather tires are all highway standards... and that’s just for cars. Given how much we drive—and how many vehicles we own—it’s no surprise that the global automotive tire market is predicted to balloon to a worth of $154 billion within the next six years.

So what happens to those rubber tires after the life has worn out of them?

AN INCREASE IN RUBBER WASTE

In the days of Henry Ford, cars were still a novelty. Today we rely on our vehicles—nearly two per household, on average—more than ever before.

In fact, estimates say about one tire per person per year is discarded in North America. That’s just shy of 375 million rubber tires landing in local incinerators, landfills, and even rivers and lakes every year.

While natural rubber is derived from plants, making it biodegradable, most modern rubber products use man-made synthetic polymers found in petroleum crude oil. Even those tires on a new hybrid vehicle aren’t going to break down naturally over time. And while a front-yard tire swing does a nice job of recycling, the sheer amount of tire waste piling up in junkyards is quickly spinning out of control.

This is where industrial rubber recycling comes in.

NORTH WEST RUBBER: LEADERS IN RUBBER RECYCLING

When North West Rubber (NWR) opened its doors in 1968, recycling—let alone rubber recycling was hardly on anyone’s radar. But every great idea needs a community champion and a rolling start.

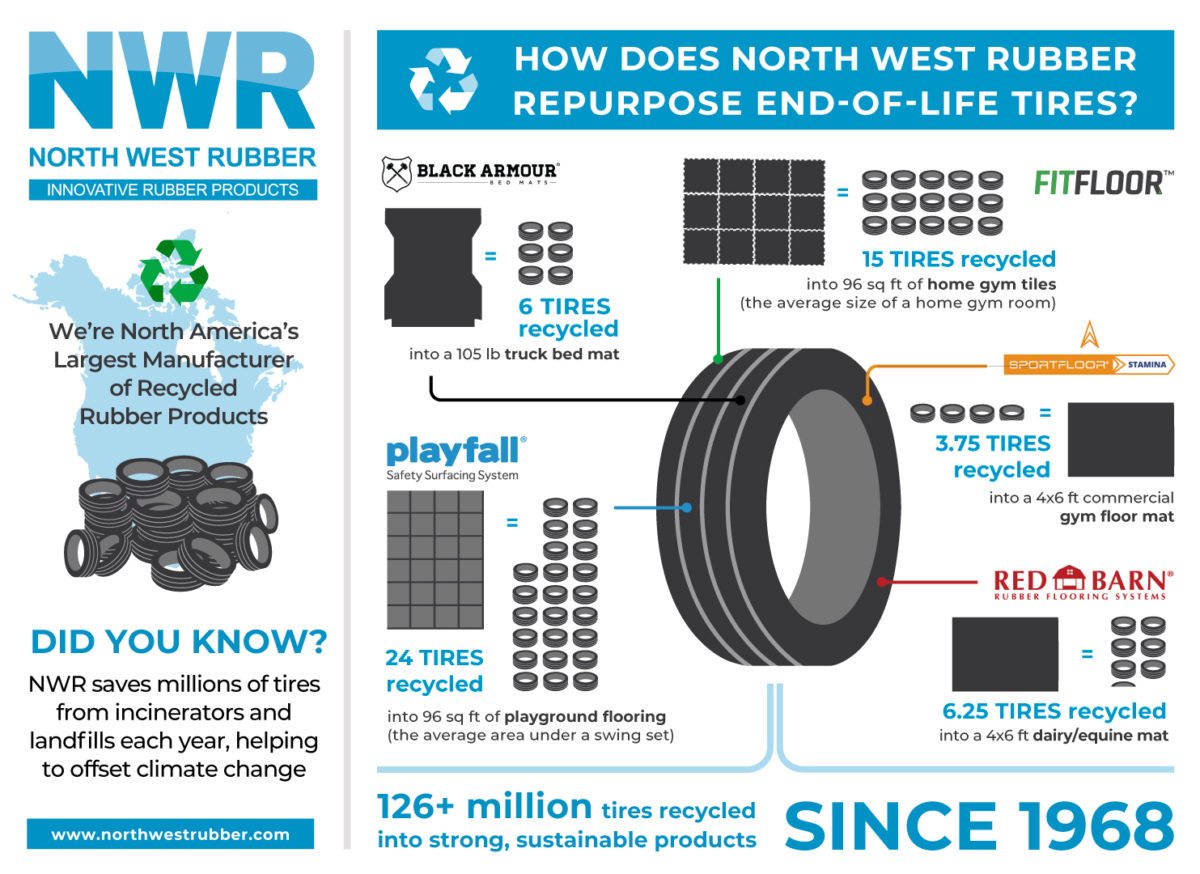

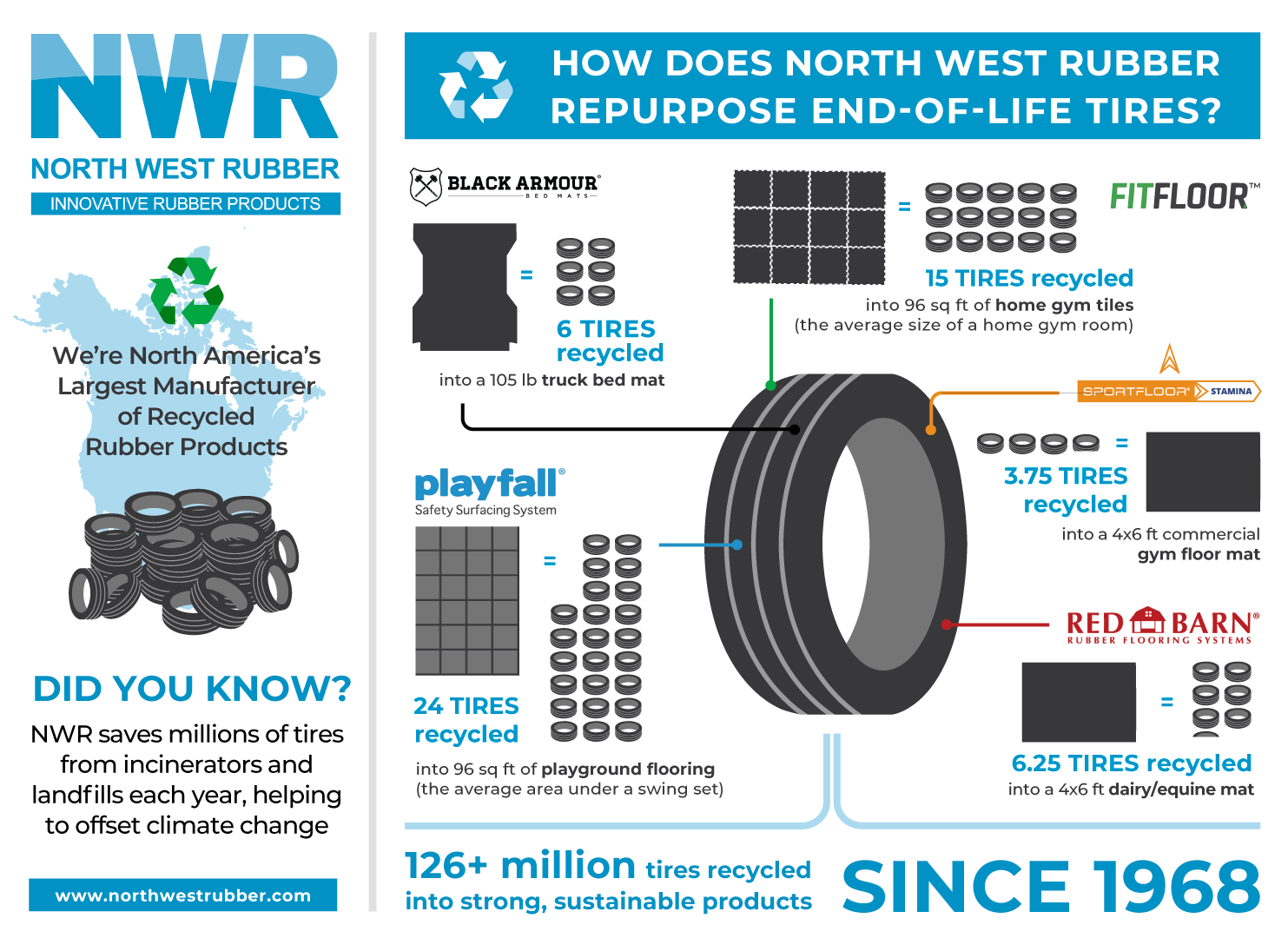

Today, NWR is North America’s largest manufacturer of recycled rubber products. In more than 50 years of operation, the company has transformed well over a billion pounds of scrap tire rubber into useful vulcanized rubber products.

So how is this done? When a tire retires, so to speak, it’s either sent to be disposed of, or to be recycled. Companies like our friends at Western Rubber, a division of Liberty Tire, will shred that tire into smaller rubber shards. NWR then takes that recycled rubber crumb and fuses it together under extreme heat and pressure to form a solid, non-porous rubber mass. This vulcanization process creates a hygienic surface which repels moisture and bacteria collection. It also creates an ultra-dense, longer lasting finished product, with up to 20% more rubber than polyurethane-bound rubber products.

Over the past five decades, NWR has transformed well over 126 million tires that equates to 1.8 billion pounds of scrap tire rubber into useful, recycled products with a clean energy, closed-loop production process which

generates virtually zero rubber waste during manufacturing. And they’ve looked to the community—from cattle and equine farmers, to professional truck drivers and athletes—to help determine where end-of-life tires could be repurposed into useful rubber products!